The steaming systems are used to change the plastic characteristics, and colour of the wood and to disinfect against pathogens and insects. The steaming process consists of maintaining the wood in a saturated steam environment.

The temperature and time required for the process are determined by the type of wood and by the result to be obtained (more or less intense colour).

The steamers can be operated with superheated water at a min. of 119°C, steam, diathermic oil or through direct gas burner.

The steaming process can be performed using two systems:

►VPL-i and VPL-iB systems with indirect steam generation;

►VPL-d systems with direct steam generation;

Drying Kilns

Advanced Timber Drying Technology

We offer you the best technology in the wood drying sector

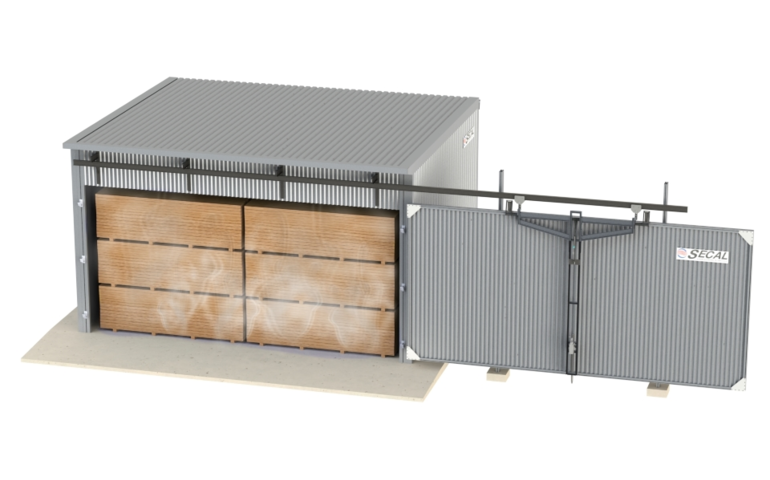

For more than 20 years, SECAL has been manufacturing timber drying equipment and technologies.

Thousands of installations throughout the world attest to SECAL’s ability to offer excellent solutions for drying any type of wood.

The innovative technologies developed have made it one of the world’s leading manufacturers of timber dryers and number one when it comes to the Global Quality of its products.

The SECAL brand is today synonymous with QUALITY, a goal achieved through technological development and ongoing research applied to each component.

This quality is also found in the other production lines:

heat treatment chambers for wood packaging and pallets in compliance with the ISPM 15 FAO regulation

steaming chambers

kilns for drying firewood

turnkey systems complete with biomass boilers and every accessory

special chambers for drying hygroscopic materials other than wood